Instead the engineering giant will now buy its heavy pressure vessels from a third party supplier.

The large, metal components sit at the heart of nuclear reactors and must be able to withstand extremely high temperatures and pressures. They are only made by a select group of companies, partly due to the need for specialist welding techniques.

Among their number is now Sheffield Forgemasters, which was nationalised by the Ministry of Defence in 2021.

Earlier this month, Sheffield became the sole UK company to gain the qualifications needed to make SMR reactor vessel components.

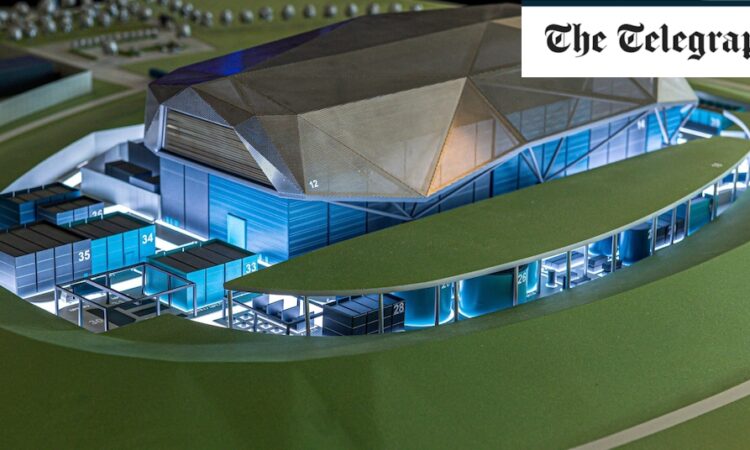

Despite having shelved its plans for a heavy pressure vessel factory, Rolls is still pressing ahead with plans to build its second factory, which will build the modular units that make up its SMRs.

It is understood that sites shortlisted for the pressure vessel factory will also be contenders for the second plant but no decisions have been made.

On Friday, a spokesman for Rolls-Royce SMR confirmed the company had now “prioritised work on our modules assembly and test facility”, adding: “Our efforts are focused on identifying the best site to support our deployment at pace.”

The company has also not ruled out reviving its plan for a heavy pressure vessel factory at some point in the future, so long as it manages to build up a healthy pipeline of orders.

A Government spokesman said: “Our world leading SMR competition aims to be the fastest of its kind, helping secure billions in investment for the UK, meaning cleaner, cheaper and more secure energy in the long-term.”