Estimated reading time 4 minutes, 46 seconds.

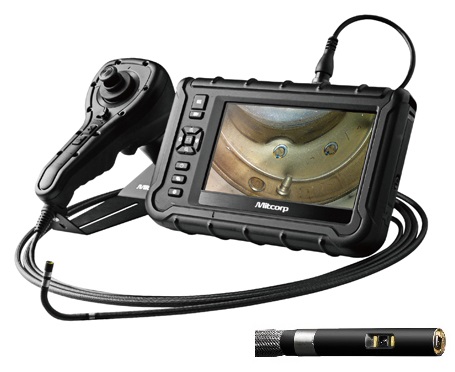

As a global supplier of world-class visual inspection equipment, USA Borescopes are a one-stop source for aviation and aerospace professionals worldwide. With a complete catalog of small .5 mm fiberscope, a Rigid Borescope, a fully articulating aviation borescope, or an Intrinsically Safe Pipe Inspection System, even if you are unsure what would be the best device for your application, a trained specialist can help.

Due to the advents in optical technology and modern electronics, we’ve seen advancements in the borescope industry. Modern borescope devices have made inspections easier and enabled aviation businesses and organizations to monitor their engine components’ performance more effectively. In this article, we’ll discuss the importance of borescope inspections and how they can ensure operational safety and save valuable time and money.

Save time effortlessly

Most aviation and aerospace industry borescopes offer a flexible probe that allows the inspection device to snake around access ports and borescope guide tubes. At the probe’s tip, a micro camera sends an image digitally to a color viewing screen. The borescope also provides lighting on the probe’s tip to illuminate the inspection area.

Borescopes help aviation inspectors and maintenance professionals to identify issues effortlessly within a short period. A small entry point is required to introduce a borescope into the inspection areas, as most aviation borescopes are designed with 4 – 6mm diameter probes. This feature, in turn, can save the user’s time by reducing his or her workload.

Maximized savings

Inspecting the internal condition of an aviation engine is an important maintenance activity, but dismantling an engine is a long and time-consuming process. Borescope inspections offer an optimal way to minimize effort while obtaining the required data to evaluate condition and performance.

The simplicity of data collection with image capture and video recording of borescopes comes in quite handy in the inspection process. Most borescopes will offer these features with a push of a button that will store inspection data on a removable SD card. Once the data is documented, it can easily be stored or shared with customers or other disciplines within the organization. The collected inspection data will dictate what follow-on maintenance must take place and the priority of the work.

Long-term benefits

Aviation engines can provide decades of reliable service, whether it is a commercial or business-focused vessel. Either way, the data that has been collected by the borescope inspection will aid in assessing if the system has aged well or if conditions have changed.

Ten years from now, when it is time to conduct another significant inspection, the team performing the work will be able to look back at Baseload Power’s documentation with confidence. Either they will find that the system aged well or that conditions have declined over time. Regardless, the borescope inspection will serve its purpose of saving time and money.

To learn more about USA Borescopes’ extensive line of aviation and aerospace scopes, visit usaborescopes.com.